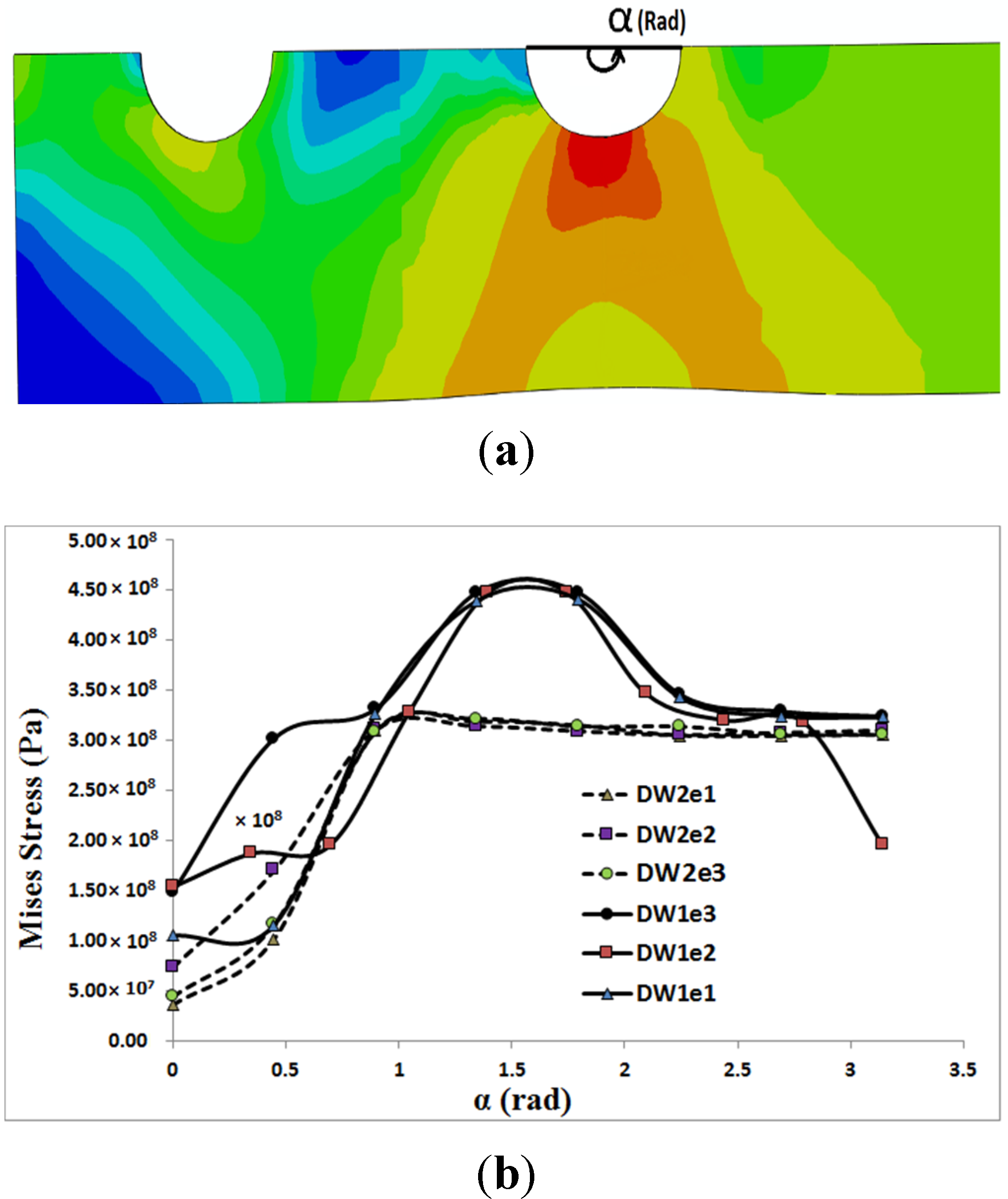

To evaluate the effect of the specimen design on the flexural strength σf and failure mode of ceramic structures testing the hypothesis that the ceramic material under tension controls the mechanical performance of the structure.

Ceramic failure mode tension.

Failure in tension this failure occurs when you stretch a material bit too far.

The tensile experimental results revealed that the zirconium diboride silicon carbide ceramic composite is rate sensitive in terms of the tensile strength and failure mode.

There are two important factors to consider when choosing the terminology used to.

The dynamic tensile strength increases linearly with the loading rate and changes from 195 mpa at 7 53 gp s 1 to 654 mpa at 74 71 gp s 1.

The fracture resistance failure mode and failure origin in bilayered ceramics tested to represent the clinical failure mode of all ceramic crowns and fpds are dependent upon the interfacial surface roughness and the modulus of the material in tension.

Clearly the failure mode is linked directly to the failure mechanism.

Multilayer ceramic capacitors prepared from various mid k and high k barium titanate based laboratory compositions were studied to understand the conduction and failure mechanisms.

Failure modes in ceramic based layer structures.

Unlike non prestressed flexural elements the initiation of a web shear crack leads to an immediate and unstable crack propagation across the section.

When this composite structure is heated the electrodes tend to force the capacitor apart.

Transverse fracture in multilayers from tension and line wedge indentation international journal of fracture 10 1007 s10704 007 9129 7 145 4.

Ceramics are weak in tension and strong in compression.

Tensile forces encourage crack formation and propagation.

But let me make a point over here.

The possibilities of this is very rare if the structure is designed properly.

Click a pore can exist in anything but let s consider a non crystalline phase for the time being.

If the terms used to describe the failure mode are meaningful it will be possible to identify that linkage.

A basis for materials design of dental crowns.

Around 20 ppm c and ceramic with a cte of 10 12 ppm c.

The next steps are the presence of the failure mode and occurrence of the failure.

This tendency is made worse by ag pd being a much better conductor of heat 400 w m k than ceramic 4 5 w m k so that a thermal gradient will exist across the ceramic layer.

Let s look at a simple pore.

For these laboratory ceramics two types of failure modes called avalanche breakdown or abd and thermal runaway or tra were found.